Seametrics TX80 Series Manuel d'utilisateur

Naviguer en ligne ou télécharger Manuel d'utilisateur pour Équipement Seametrics TX80 Series. Seametrics TX80 Series User Manual Manuel d'utilisatio

- Page / 4

- Table des matières

- MARQUE LIVRES

Noté. / 5. Basé sur avis des utilisateurs

Sensor

Hall Effect Sensor 12 VDC current

sinking pulse

Materials

Sensor Body Polypro, Brass, 316 SS

Rotor Polypro, PVDF optional

Shaft Nickel-bound tungsten

carbide,zirconia ceramic

optional

Bearings Ruby

Range 0.2 - 30 FPS (0.06-9.14M/s)

Acuracy

± 1% FS

Maximum Pressure

Polypro 175 psi @ 75° F (12 bar)

Brass 200 (14 bar)

316 SS 250 psi (17 bar)

Maximum Temperature

Polypro 130° F (55° C) at 0 psi

Brass, SS 200° F (93° C)

Power 6-24VDC, 8 mA

Nominal K-factor 11 Hz/FPS (3.6 HzM/s)

Cable #22 AWG 3-con 18' (6m)

Maximum Cable Run 2,000' (650m)

Flow Range (GPM)

Specifications

General Information

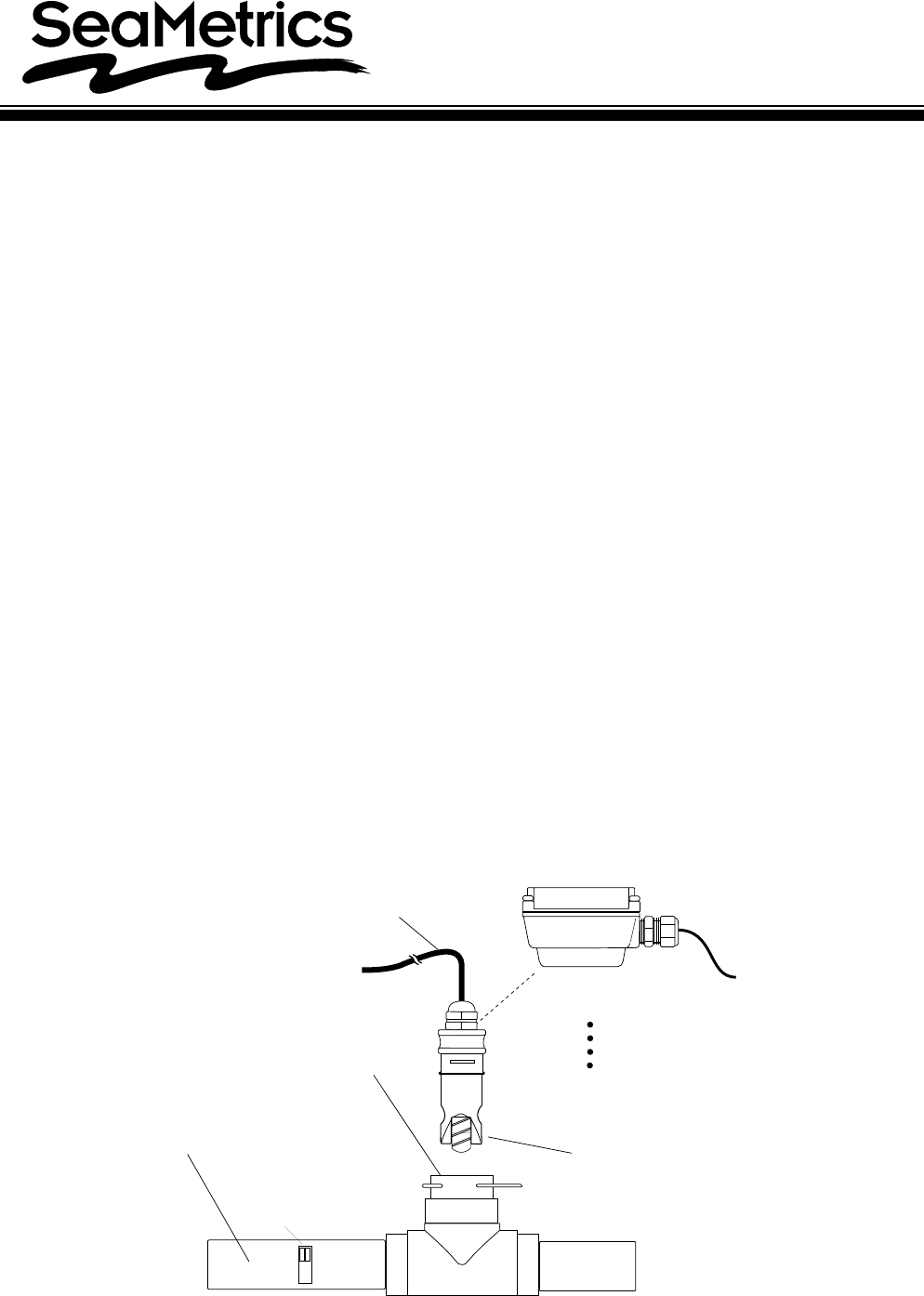

The TX80 Series are turbine-type insertion meters de-

signed for use in pipe sizes 1" to 8". High-quality jewel

bearings and nickel-bound tungsten carbide shaft are

used for maximum life and extreme low friction. Bodies

are machined from solid rod for maximum precision. Low-

flow performance is superior. The rotation of the rotor is

detected by a non-drag Hall-effect sensor. Output is a

pulse-type square wave, which can be sent long dis-

tances (up to 2,000 feet) without a transmitter. This sig-

nal can be connected directly to SeaMetrics controls, as

well as PLC's, counters, and computer cards.

SeaMetrics TX80 meters are ideal for chemical propor-

tioning applications. If no display is required, a simple

divider such as the PD10 provides adjustable pump pac-

ing. For rate and total display, as well as pump pacing,

the FT420 flow indicator can be mounted directly on the

TX80 Series, or remotely on a wall or panel.

The TX80 Series require special fittings, since they are

not depth-adjustable, installation in the fitting ensures

correct depth placement in the pipe. Fittings are avail-

able in PVC, brass, and stainless steel. Sensors are avail-

able in brass, 316 stainless steel, and polypropylene. In

plastic pipe 3"-8", use an IP82 sensor, which is 1.00"

longer than the IP81 to accommodate the larger fittings.

LT-10614A

Page 1 of 4

Features

TX80 Series Flow

Sensor Instructions

Pipe stubs provided

for ease of installation.

Solvent weld

or

male NPT

Each fitting individually

calibrated and marked

with K-factor

(Pulses per Gallon)

Fitting automatically

sets probe at correct

depth and orientation

Jewel bearings for

superior low-flow

performance.

Threaded housings

allow for field repair

MODEL

SERIAL

High level (12 VDC)

signal can be sent

up to 2000+ feet

without transmitter

Meter mount option

for electronics:

Rate/Total

4- 20 mA blind transmitter

Pulse Divider

Battery Rate/Total

Min.

Max.

1" 1-1/2" 2" 3" 4" 6" 8"

0.8 1.9 3.1 6.9 12 27 47

80 190 314 691 1200 2700 4700

Résumé du contenu

Page 1 - Sensor Instructions

SensorHall Effect Sensor 12 VDC currentsinking pulseMaterialsSensor Body Polypro, Brass, 316 SSRotor Polypro, PVDF optionalShaft Nickel-bound tungsten

Page 2 - TX80 Series Connections

InstallationFitting Installation. TX80 Series meters require spe-cial fittings. The meter fitting must first be installed in thepipeline. Straight

Page 3 - Maintenance and Repair

Maintenance and RepairRotor Replacement. It is unusual for a rotor to requirereplacement due to damage sustained in normalservice. More commonly, t

Page 4

20419 80th Ave. So., Kent WA. 98032 USAPhone: 253-872-0284 Fax: 253-872-0285www.seametrics.com 1-800-975-81534 of 4gnitsiLstraP28,18XT1gnisuohreppU1

(12 pages)

(12 pages)

Commentaires sur ces manuels